This article is going a little bit technical so we will go straight forward to the points.

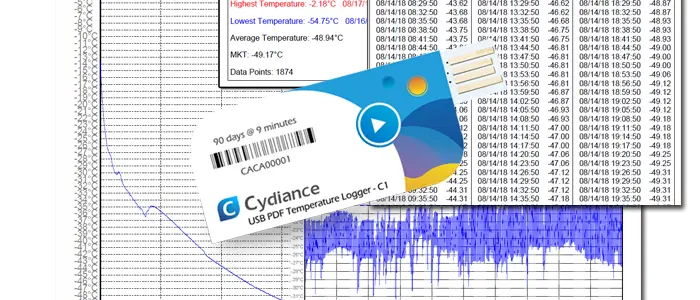

USB temperature logger is proved to be the most popular option for recording transit temperature in most logistic applications.

The design is quite simple with this product, but the details behind it are never that simple.

Key factor 1: Real traceability

All loggers collect temperature, with 2 options: an “internal NTC” or a “digital sensor”.

Internal NTC is widely used in most low-end loggers, because of its low cost. Not only itself is cheap(around $0.03), but also the complete onboard system to support it can be built at a low cost. The digital sensor is more expensive and requires more onboard resource to support.

The difference? Calibration and accuracy. NTC is not always calibrated because, it’s almost impossible to do a 3-point NIST calibration for each NTC, and an uncalibrated NTC can be ±2℃ away from accuracy. While the digital sensor is pre-calibrated to NIST from its manufacturer and is guaranteed for certain accuracy, it, however, requests more stable system support, especially in low-temperature low voltage conditions.

In our case, Cydiance uses digital sensors in all loggers, including USB/Bluetooth and realtime, no exception. And we do the 3-point calibration with NIST traceable equipment again based on percentage, all process are recorded in internal ERP system for the documentary.

Key factor 2: Low temperature performance

Make sure you get a logger that can work to -30 Celsius if you are shipping something frozen.

You may well say your frozen shipment is only setting to -18℃, but wait, you never know it may experience temperature lower than -26℃ during the working period of the refrigerator, and especially when the problem happens, it goes down to even lower. And the point is, when shit happens, these data are exactly the ones we looking for.

Something for your attention, a recent test from us to 9 brands data loggers, 7 of them failed in the low-temperature test. Don’t lose your records when your fresh chilled products got frozen.

Key factor 3: Failure proof strategy

All electronic device will make mistakes, therefor a “failure proof strategy” has to be deployed internally. For example, anti-static proof, compatibility, low voltage, non-stable connection etc.

USB temperature logger should be prepared for all these unexpected coincidences, and make sure the integrity of the content is kept. A good logger would be confident to work with an old computer with a non-stable voltage USB port and perform as normal.

This is a factor quite difficult to be proved especially when you are only using several units, but when failure happens, it will cause you a huge problem and loss with your load.

In our case, we have a very complex system on this simple product, both hardware and firmware, to ensure it fix itself when something happens. If you check our on-board works, you will notice we have 30% more components than industry, everything to make it stable.

We can continue with a lot more to share, but we believe these above should be the most important factors to consider before you make your decisions.

Recording temperature is easy, providing complete and reliable data is never easy.